الوصف

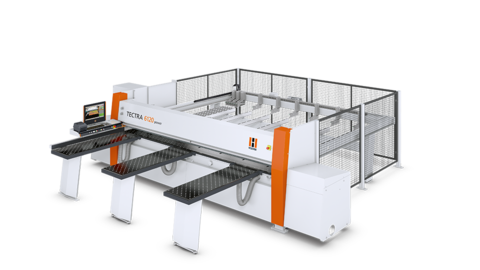

TECTRA 6120 power

Saw Blade Protrusion up to 95 mm

Sawing Unit: up to 15 kW

Cutting Lengths: up to 4,400 mm

Cutting Widths: up to 4,300 mm

Professional Software Package

Pneumatically Controlled Angle Presser

Angle Cutting Unit

10 Year Guarantee on All Linear Guides

Technical Details

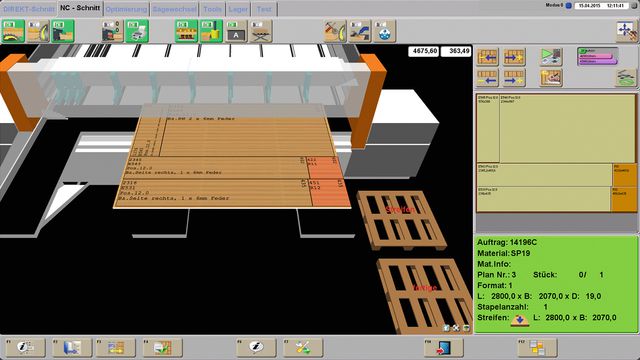

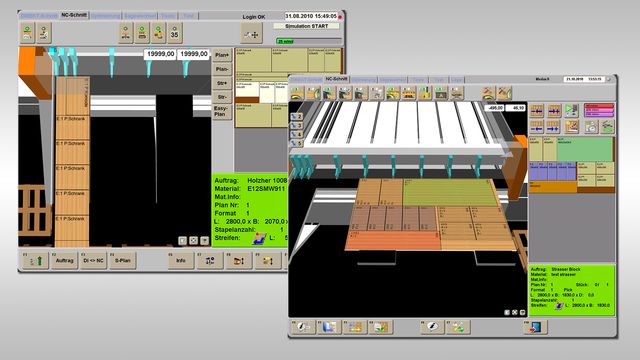

The CUT CONTROL 2 control package

The control is decisive for the power output of a state-of-the-art pressure beam saw. The TECTRA series is controlled by our CUTCONTROL 2 and the preinstalled EASY-PLAN and OPTI-CUT software packages.

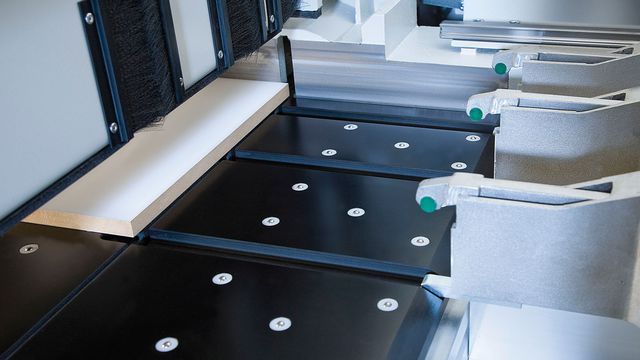

Solid air cushion tables

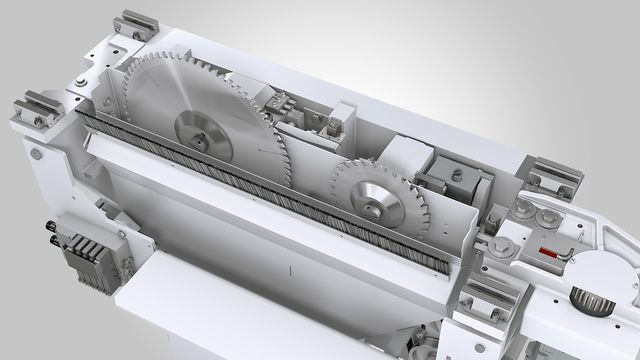

The sawing unit of the TECTRA series

Main sawing motor 11 kW – for optimum sawing capacity for stacks or high speed rough cuts – max. saw blade protrusion of 82 mm.

Sawing carriage – with a saw blade diameter of 350 mm, the automatic, infinite cutting height adjustment ensures optimum saw blade protrusion for cleanly cut edges.

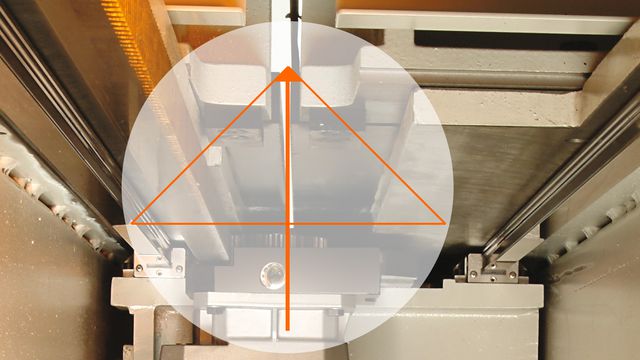

Motor-driven groove height adjustment – adjustable groove depth from 0 – 30 mm programmable on control and optimization.

Bidirectional grooving program in Fast Cut Mode (FCM) – Guarantees shortest possible cycle times for grooving – grooving is also accomplished during sawing carriage return!

Automatic cutting length limitation – A proximity-type optical feature recognizes the end of the workpiece – eliminating unnecessary sawing carriage travel, especially for manual cuts.

Optimized automatic cutting length feature – The sawing carriage is controlled by the optimization feature – the sawing carriage is prepositioned beneath the panel, the start and end of the cut are calculated, paths without cutting are traversed at maximum speed.

Electrically adjustable prescoring saw – Allows simple and perfect adjustment of the prescoring saw on the monitor, in the shortest possible time, with minimum effort.

High performance postforming unit (optional) – High performance postforming unit for tear-free cutting of postformed and other edges up to a panel thickness of 50 mm.

Quick-change clamping system for main and prescoring saws – Ensures precisely clamped saw blades and extremely short standstill times for changing saws.

Central, traveling evacuation – Dust is picked up precisely where it is produced.

Freely programmable rip fence

The ‘power’ workpiece clamps

Remnant cutting device integrated into the pressure beam

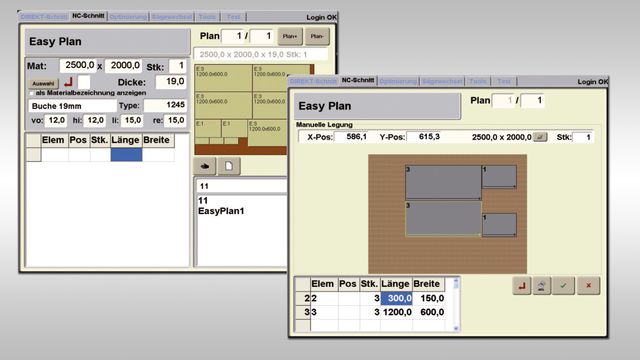

Optimization module EASY-PLAN

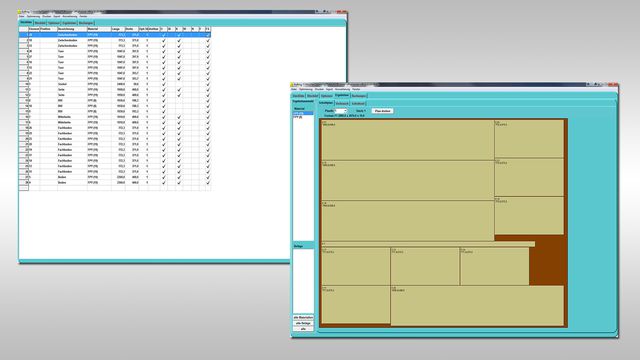

Optimization module OPTI-CUT

Optimization module OPTI-PRO

المراجعات

لا توجد مراجعات بعد.